-

+86 13383895687

Stainless Steel Heavy Duty Load-Bearing Shelve

PRODUCT PARAMETERS

- Material: 201/304 Stainless Steel(Column: 1.0mm, Beam: 0.8mm)

- Default Dimensions: 2000L × 600W × 2000H (mm),Can be customized according to a user

- Load Capacity per Layer: 500-600kg (Static load with even distribution)

- Number of Layers: Standard 3 layers (Customizable: 2-4 layers)

- Height Adjustment Range: Adjustable in 5cm increments (±10cm per layer)

- Column Spacing: Adjustable buckle design

- Surface Treatment: Brushed anti-rust finish + Anti-static coating (optional)

- Installation Method: Bolted assembly (no welding required) with pre-drilled holes

- Operating Temperature: -30℃ to 80℃ (Extreme conditions require customized coating)

Description

Overview of heavy-duty load-bearing shelves

Heavy duty load-bearing shelves are designed for medium-strength storage needs, suitable for scenarios that require frequent access and moderate weight of goods. The main body is made of 201 / 304 stainless steel, the thickness of the column is raised to 1.0mm, and the beam is double-welded. The single-layer load-bearing capacity covers 500-600kg, taking into account strength and cost efficiency. The shelf height supports ± 10cm flexible adjustment. Anti-skid strips and corner guards are added on the edge of the laminate to prevent the goods from slipping.

The modular structure design supports horizontal multi-group splicing, which is easy to expand into a storage system, and the reserved width of the forklift channel can be customized. The surface is treated with brushed anti-rust and anti-static coating to withstand the dust and oil environment of the factory workshop and, at the same time, meet the anti-static needs of electronic manufacturing and other scenarios.

Characteristics of heavy load-bearing shelves

High-standard material: The main body is made of 201 / 304 stainless steel, with a column thickness of 1.0mm and a beam thickness of 0.8mm. The corrosion resistance is better than that of conventional steel, and there is no deformation after long-term use.

Load-bearing strengthening: single-layer load-bearing 500-600kg, double-layer reinforcement welding is used at the connection between the beam and the column, which can be adapted to the frequent access operation of forklifts.

Flexible adjustment: every 10cm of floor height is an adjustment unit (± 10cm range), compatible with different height cargo boxes or pallets, and the laminates can be disassembled and replaced.

Loss-proof design: anti-skid rubber strips are installed on the edge of the laminate, and removable anti-collision corners are arranged at the four corners to avoid scratching shelves or personnel during cargo handling.

Environmental adaptation: surface wire drawing treatment anti-rust, optional anti-static coating (surface resistance ≤ 10Ω), suitable for unique environments such as electronic workshops and chemical warehouses.

Easy to expand: support horizontal multi-group splicing, reserve forklift access (default 1.5m, can be customized), single-group shelves can be extended to a continuous storage system.

Quick installation: pre-drilling position design, accessories include labeled screw sets, single-person installation can be completed within 15 minutes, no need for on-site welding.

Parameters of heavy load-bearing shelves

| Parameter | Specification |

| Material | 201/304 Stainless Steel(Column: 1.0mm, Beam: 0.8mm), the thickness can be customized according to a user’s request |

| Default Dimensions | 2000L × 600W × 2000H (mm),Can be customized according to a user |

| Load Capacity per Layer | 500-600kg (Static load with even distribution) |

| Number of Layers | Standard 3 layers (Customizable: 2-4 layers) |

| Height Adjustment Range | Adjustable in 5cm increments (±10cm per layer) |

| Column Spacing | Adjustable buckle design |

| Surface Treatment | Brushed anti-rust finish + Anti-static coating (optional) |

| Installation Method | Bolted assembly (no welding required) with pre-drilled holes |

| Operating Temperature | -30℃ to 80℃ (Extreme conditions require customized coating) |

Application of medium load-bearing shelves

Heavy-duty load-bearing shelves are mainly aimed at scenarios where there is a balance between storage efficiency and load-bearing capacity. They are suitable for high-frequency access to medium-weight goods. Its core applications include:

- Manufacturing workshop

- Auto parts storage: Store engine components, transmissions, tires and other medium-sized components, and the shelf height can be adapted to different specifications of parts boxes.

- Mold and fixture management: support 500-600kg metal molds, beam anti-skid design to avoid displacement, and cooperate with the workshop forklift to dispatch quickly.

- Logistics transit warehouse

Standardized pallet temporary storage: bulk storage of electronic products, home appliances and other medium-sized goods, support forklift direct loading and unloading.

- Cross-warehouse operation area: used for sorting and transit, with an open shelf structure for quick code scanning and cargo mobility management.

- Chemical and food processing

Storage in raw material barrels: 201 Stainless Steel /304 Stainless Steel is resistant to acid and alkali corrosion, suitable for layered storage in chemical raw material barrels (200L standard barrels) or food additive containers.

- Clean workshop: Anti-static coating is used in electronic components and precision instrument warehouses to avoid dust adsorption and static interference.

- Supermarkets and wholesale markets

- Back warehouse inventory optimization: stores seasonal goods (such as holiday gift boxes and promotional beverages), and the laminate load-bearing adapts to the stacking of the whole box of goods (≤ 3 layers).

- Frozen product cold storage: It will not rust for long-term use at -25 ° C and will store frozen food boxes or cold chain packaging boxes.

- Auto repair and mechanical repair

- Facility Management: Heavy maintenance tools, hydraulic equipment classified shelves, anti-collision corner protection shelves and personnel safety.

- Tire storage: The width of the laminate is suitable for car/SUV tires to be placed vertically, and the single-layer load-bearing supports 20-30 tires to be stacked densely.

- Medical equipment storage

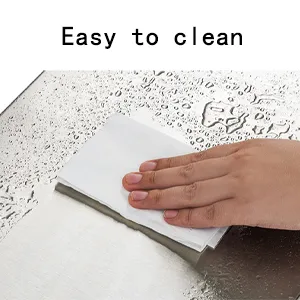

- Dust-proof storage of medium-sized medical instruments (e.g., ultrasound equipment, surgical carts), surface polishing for easy disinfection and cleaning.

Company profile

Luoyang Geen Office Furniture Co., Ltd. is a professional manufacturer of high-quality stainless steel furniture. The company is equipped with professional production equipment and production lines, and is supported by a team of more than 60 experienced experts.

We offer various stainless steel products, including load-bearing shelves, tool cabinets, medicine cabinets, locker cabinets, file cabinets, office desks, commercial furniture, office furniture, kitchen furniture, fire equipment cabinets, etc. Our products are widely used in schools, offices, factory workshops, medical institutions, production lines, warehouses, gyms, clubs, lounges, cloakrooms, changing rooms, storage cabinet rooms, sports facilities, greenhouses, as well as other application scenarios.

We are dedicated to providing you with high-quality stainless steel furniture. If you have any questions about our products, please feel free to contact us at any time. We welcome you to discuss cooperation with us.

Tel:+86 13383895687

Wechat: +86 13383895687

Whatsapp: +86 13383895687

Email: sales@stainlesssteelcabinets.net

Payment method

T/T, Western Union, Paypal, Credit Card etc.

Shipping method

Packaging standards:

-Depending on the product and quantity, regular packaging is film and corrugated boxes. Mail parcels and other special packaging can be customized according to your needs.

– Mode of transportation:

– Air freight, sea freight, express delivery, according to your requirements.

Heavy duty load-bearing shelves FAQ

Q1: Can the shelf come into direct contact with chemical liquids (such as acids and bases)?

- It can withstand weak acid and alkali environments (pH 5-9). If it comes into contact with highly corrosive liquids (such as concentrated sulfuric acid) for a long time. In that case, it is necessary to customize thickened coatings or use PP laminates (at an additional cost).

Q2: Is the connection between the beam and the column easy to loosen?

- With a three-hole bolt reinforcement design and anti-loosening spacer, there is no risk of loosening when the forklift is accessed and operated less than 20 times a day. It is recommended to check the bolt torque (standard value 25N · m) every six months.

Q3: Can the shelf laminate hold special-shaped goods (such as cylindrical barrels)?

- The laminate is equipped with anti-skid strips as standard, which can fix drums with a diameter of more than 300mm; if the diameter of the goods is less than 300mm, a limit bracket needs to be installed (accessory library code: CL-02).

Q4: Does it require special treatment for use in cold storage at -30 ° C?

- The standard model can be directly used in an environment of -30 ° C. Still, in areas where condensate comes into frequent contact (such as the door of the cold storage), it is recommended to choose a low-temperature anti-rust coating (surface freezing point tolerance -50 ° C).

Q5: Can the shelves be integrated with automated storage systems (e.g., AGV trolleys)?

- To support AGV access, the following conditions must be met:

- The spacing of the shelf groups is ≥ 1.8m (to ensure the steering space of the trolley);

- The height of the bottom of the shelf from the ground is ≥ 15cm (compatible with the thickness of mainstream AGV forks).

Q6: How to install uneven ground?

- Provide adjustable anchor bolts (accessory library code: DJ-03), support ± 3cm height compensation, and do ground leveling first when the inclination error is > 3 °.

Q7: How long is the valid period of the anti-static coating?

- Under regular use (without scratching from complex objects), the anti-static performance is maintained for 5-8 years and can be regularly verified by a surface resistance detector (e.g., ME2683A).

Q8: Can the shelves be used in the open air?

- For short-term (< 6 months) open-air storage, a rain shelter needs to be installed; for long-term outdoor use, a custom-made outdoor model is required (zinc-chromium coating is added, and the cost is + 15%).

Q9: What is the maximum expansion length of a single set of shelves?

- Horizontal continuous splicing should not exceed six groups (total length ≤ 12m), and extra long column support should be added (one group every 4m).