-

+86 13383895687

Stainless Steel Cleaning Cabinets

Stainless Steel Four-Grid Cleaning Cabinet

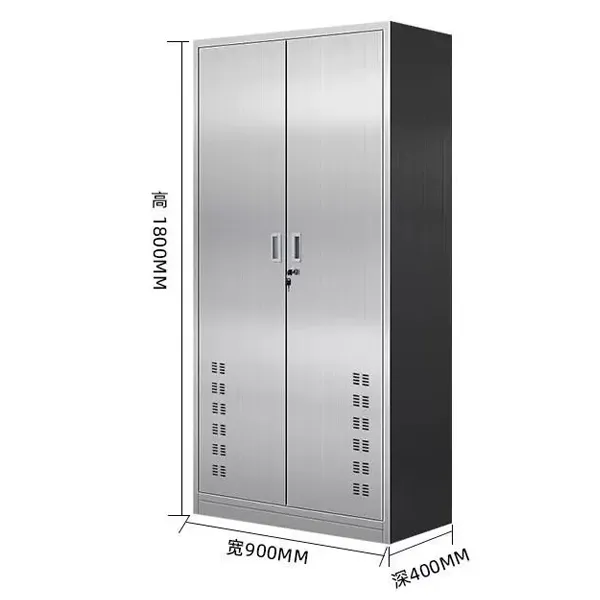

Stainless Steel Double Door Cleaning Cabinet

Single Door Cleaning Cabinet

Stainless steel cleaning cabinet overview

The stainless steel cleaning cabinet is a professional storage device developed for the management needs of cleaning tools in public places. It adopts 201/304 double series stainless steel material to build an efficient management system of "partition storage + moisture-proof ventilation". It is suitable for the classified storage of cleaning tools such as brooms, mops, cleaners, trash cans, etc. The dual material system takes into account economy and corrosion resistance. The fully enclosed cabinet is matched with adjustable laminates and a drain design. It is suitable for high-frequency cleaning scenarios such as hotels, hospitals, enterprises, and commercial complexes. Through structural optimization and functional subdivision, the orderly management of cleaning tools and the improvement of environmental cleanliness are realized.

Characteristics of stainless steel cleaning cabinets

Dual material durable system

201 Economy Stainless Steel

Material characteristics: The thickness of the plate is 0.5mm, and the cost is 30-33% lower than that of 304 models. It is suitable for dry environments, such as northern office buildings and ordinary shopping malls.

Surface treatment: brushed satin, daily fingerprint resistance to meet high-frequency use scenarios, detergent residues can be wiped directly with a damp cloth.

304 medical-grade stainless steel

Material characteristics: The thickness of the plate is 0.5mm, and the corrosion resistance is several times that of the 201 model. It is suitable for humid environments (such as coastal hotels, hospital disinfection areas, and underground garages).

Safety advantages: It can store cleaning tools after disinfection, withstand chlorine-containing disinfectant wiping, and meet hospital sensory control standards.

Partitioned storage system

Tool suspension area (2-4 grids)

Built-in stainless steel hanging rod (diameter 10mm), single rod bearing 15kg, can hang broom, mop (handle length ≤ 1.6m), rod spacing 200mm to avoid entanglement; bottom set 30mm high drain table, tilted 5 ° design to guide water flow to the bottom of the cabinet drain hole (φ 10mm).

Consumables storage area

Equipped with 1-2 sets of adjustable laminates (5-speed adjustment, 50mm interval), the layer height range is 150-300mm, and it can store 4L detergent buckets (single-layer 2-4 buckets), 20L trash cans (inverted storage) or cleaning cloth storage boxes. The laminates bear 20kg (uniform load).

Sealing and ventilation

The cabinet door is sealed with a sealing strip to isolate odors when closed; 4-6 φ 50mm ventilation holes (built-in insect net) are installed on the top of the cabinet to maintain internal air circulation and reduce the growth of mold (relative humidity control ≤ 60%).

Industrial-grade process details

Welded structure

Spot welding design, no sanitary dead ends, easy to use a damp cloth for deep cleaning.

Double surface treatment

Satin brushed: The surface is delicate and non-slip, with strong weather resistance (no obvious oxidation after outdoor exposure for 1 year), suitable for high-frequency contact cleaning rooms; fingerprints and stains can be quickly wiped and removed.

Matte matte (optional for customization): The anti-fingerprint effect is increased by 40%, which is suitable for the concealed clean room design of high-end hotels.

Safe and convenient configuration

Adjustable anchor system

The bottom is equipped with 4 ± 30mm adjustable steel feet, which are suitable for uneven floors (such as floor tile height difference and slope cleaning room). Floor-to-ceiling installation does not require wall load-bearing and has strong stability.

Security lock

Standard C-class mechanical lock, optional electronic combination lock to protect the safety of chemicals such as detergents and avoid contact with children or unrelated personnel.

Application of stainless steel cleaning cabinet

Hotel/commercial complex

Multi-area management: 304 bathroom cleaning rooms suitable for damp, dry and wet mops are hung in partitions (special tools for distinguishing "public areas" from "toilets"), hand sanitizer replenishment and garbage bags are stored in the consumables area, and locks are used to prevent the loss of cleaning supplies.

Scene advantage: make full use of the vertical space, deeply adapt to the narrow area of the corridor, and wipe the cabinet directly with a damp cloth after daily disinfection and sterilization, in line with the hotel's 5S management standards.

Hospitals/medical facilities

Sensory control requirements: 304 resistant medical disinfectants (such as chlorine-containing disinfectants, peracetic acid), UV disinfection lamps (optional) in the tool area, regular disinfection and sterilization mop bacteria (killing rate ≥ 99.9%), disposable gloves and disinfection wipes are stored in the consumables area, which meets hospital infection control standards.

Special configuration: The cleaning cabinet can be installed in the wall to reduce the occupation of passageway space, suitable for the compact layout of the cleaning room on the ward floor.

Enterprise/factory

Workshop cleaning: 304 models are suitable for workshops. Tool grids are hung with industrial brooms and dust pushes. Lubricants and cleaning cloths are stored in the consumables area. Reinforcement ribs are designed to bear load-bearing industrial-grade tools (such as large spatulas). Adjustable feet adapt to uneven workshop floors (such as epoxy floor joints).

Efficiency improvement: Four compartments are clearly divided (such as "cleaning tools", "disinfection and sterilization supplies", "waste rags," and "spare consumables"), which can be quickly accessed by cleaning personnel and reduce search time. It is suitable for large factories and storage centers.

Public facilities

Subway/high-speed rail station: 304 models are resistant to salt spray corrosion (suitable for coastal cities), locks prevent tool theft, ventilation holes are designed to reduce mold problems in humid environments, and are suitable for cleaning rooms in public areas with high traffic (such as toilets).

School/kindergarten: 201 models are cost-effective, and classroom cleaning tools and bathroom-specific tools are stored in zones to cultivate students' classification and storage habits.

Company profile

Luoyang Geen Office Furniture Co., Ltd. is a professional manufacturer of high-quality stainless steel furniture. The company is equipped with professional production equipment and production lines, and is supported by a team of more than 60 experienced experts.

We offer various stainless steel products, including load-bearing shelves, tool cabinets, medicine cabinets, locker cabinets, file cabinets, office desks, commercial furniture, office furniture, kitchen furniture, fire equipment cabinets, etc. Our products are widely used in schools, offices, factory workshops, medical institutions, production lines, warehouses, gyms, clubs, lounges, cloakrooms, changing rooms, storage cabinet rooms, sports facilities, greenhouses, as well as other application scenarios.

We are dedicated to providing you with high-quality stainless steel furniture. If you have any questions about our products, please feel free to contact us at any time. We welcome you to discuss cooperation with us.

Tel:+86 13383895687

Wechat: +86 13383895687

Whatsapp: +86 13383895687

Email: sales@stainlesssteelcabinets.net

T/T, Western Union, Paypal, Credit Card etc.

Shipping method

Packaging standards:

-Depending on the product and quantity, regular packaging is film and corrugated boxes. Mail parcels and other special packaging can be customized according to your needs.

- Mode of transportation:

- Air freight, sea freight, express delivery, according to your requirements.

Stainless steel cleaning cabinet FAQ

Q1: Do I need to install an additional drain pipe for the tool grid drain table?

- A: No additional installation is required. The inclined design of the drain table guides the water to drip naturally through the drain hole at the bottom of the cabinet. It is recommended to place a water receiving tray (bring your own) under the cabinet, especially suitable for rainy areas or cleaning rooms with frequent flushing. The water receiving tray needs to be cleaned regularly to maintain hygiene.

Q2: Can I customize the number of cells or adjust the partition ratio?

- A: Support customization and specific requirements need to be provided.

Q3: How to maintain the 201 model in a humid environment?

- A: Type 201 is suitable for environments with humidity ≤ 70%. If used in high humidity areas: ① Clean up the residual moisture of the tool in time after use; ② Wipe the inside of the cabinet with a dry cloth every week; ③ Moisture-proof agent (such as silica gel desiccant) can be placed in the cabinet to reduce the erosion of condensate on the frame.

Q4: Can the laminate store overweight cleaning equipment?

- A: The laminate in the consumable area bears 20kg (uniform load). It is recommended that the weight of a single detergent bucket should not exceed 10kg. Large equipment (such as vacuum cleaners) should be placed on the bottom floor of the cabinet to avoid deformation caused by overload of the laminate.

Q5: What is the difference between the matte model and the satin-brushed model?

- A: The matte matte model has a more delicate surface, and the anti-fingerprint effect is increased by 40%. It is suitable for concealed installation in high-end places. The satin brushed model has better anti-skid performance and is easy to wipe stains quickly. It is suitable for public cleaning rooms with high-frequency use. The two have the same corrosion resistance and can be selected according to the decoration style.